| CONNEAUT, OHIO HISTORY & GENEALOGY...................... |

The following article was found in the Plain Dealer, Cleveland, OH on June 8,

1902 - Page 41:

The article above reads as follows:

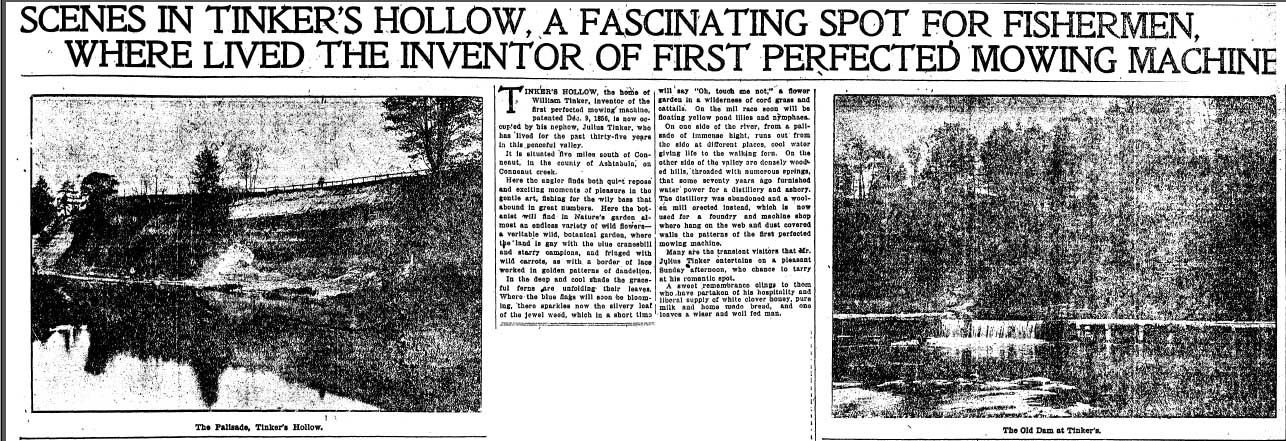

TINKER'S HOLLOW, the home of William Tinker,

inventor of the first perfected mowing machine, patented Dec. 9, 1856, is now

occupied by his nephew, Julius Tinker, who has lived for the past

thirty-five years in this peaceful valley.

It is situated five miles south of Conneaut, in the

county of Ashtabula, on Conneaut creek.

Here the angler finds both quiet repose and exciting

moments of pleasure in the gentle art, fishing for the wily bass that abound in

great numbers. Here the botanist will find in Nature's garden almost an

endless variety of wild flowers - a veritable wild, botanical garden, where the

land is gay with the blue cranesbill and starry campions, and fringed with wild

carrots, as with a border of lace worked in golden patterns of dandelion.

In the deep and cool shade the graceful ferns are

unfolding their leaves. Where the blue flags will soon be blooming, there

sparkles now the silvery leaf of the jewel weed, which in a short time will say

"Oh, touch me not," a flower garden in the wilderness of cord grass and

cattails. On the mil race soon will be floating yellow pond lillies and

nymphaes.

On one side of the river, from a palisade of immense

height, runs out from the side at different places, cool water giving life to

the walking fern. On the other side of the valley are densely wooded

hills, threaded with numerous springs, that some seventy years ago furnished

water power for a distillery and ashery. The distillery was abandoned and

a woolen mill erected instead, which is now used for a foundry and machine shop

where hang on the web and dust covered walls the patterns of the first perfected

mowing machines.

Many are the transient visitors that Mr. Julius

Tinker entertains on a pleasant Sunday afternoon, who chance to tarry at his

romantic spot.

A sweet remembrance clings to them who have partaken of

his hospitality and liberal supply of white clover honey, pure milk and home

made bread, and one loaves a wiser and well fed man.

-------------------------------------

This article was found in Plain Dealer, Cleveland, OH on Aug. 18, 1929 - pg. 1:

WORK IN IRON FOR 115 YEARS AT CONNEAUT - Members of Tinker

Family Still Practice in Arts Begun by Backsliding Sailor Forbear.

SECRET OF HARDENING IRON ISN'T REVEALED. - Only One Man Now Knows It;

Hollow Made Famous by Two Brothers.

By John W. Vance. (Staff Correspondent)

BY TINKER FAMILY

CONNEAUT, O., Aug. 17. - When a British tar, who was also a blacksmith and

homesick for the bitter smell of hot iron, jumped overboard from the deck of one

of his majesty's frigates on an early evening in 1812 and struck out for the

distant beach of Boston Harbor, he probably had no intention of founding a

dynasty of his own.

The backsliding sailor's name was Tinker

His first name is not known to the current members of his house, but still the

dominant factor in the lives of his descendants, who have been doing

unprecedented things with iron for 115 years at their home in Tinker's Hollow

five miles southwest of Conneaut.

The original Tinker, removing himself as far as

possible from ships whose deck had to be holystoned every day, reached Conneaut

some time about two years later.

Built Big Workshop.

He found Tinker's Hollow and built himself,

first, a small house, and second, a big workshop on a ridge to the south of the

hollow just above Conneaut Creek. His further deeds are lost to history.

It is probably that he died of old age, for the

Tinkers are noted, among other things, for their longevity.

He left, however, two sons, William and

Sylvester, who could swing a hammer with the best. They were men of

inquiring minds and one of the things that puzzled them was way a farmer should

do any ore manual labor than could be avoided. The idea of a mechanical

mowing machine was born.

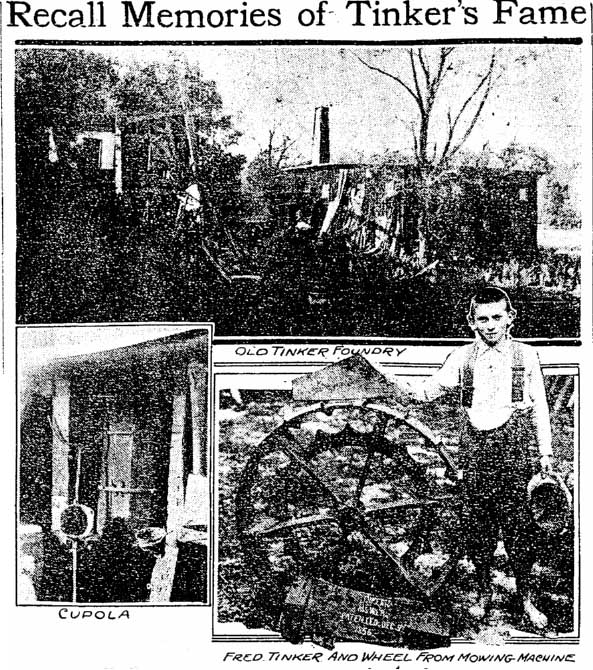

They had a new foundry, erected in 1835; they had an

iron cupola furnace, built four years later, and they had a suspicion that their

neighbors' sneers were misplaced and that a mowing machine that would work was

going to be made.

The foundry is still standing to house the work of the

present William Tinker, grandson of Sylvester. The cupola,

90 years old, the oldest in Ohio, is still fired to melt iron for its owner.

The mowing machine is gone.

William Tinker was the mechanic of the two.

Sylvester the salesman. They made a lathe for turning their

patterns, which is still in use. They diverted the waters of Conneaut

Creek and provided a ill race to turn the lathe. They designed their

mower.

A group of farmers in a hay field near Conneaut were

startled one July morning in 1853 by a dust cloud coming down the road.

The cloud was not unusual, but it was surmounted by

what looked like a plug hat. Two fat bay horses trotted in front.

Something long and thin struck out at the side.

The odd looking affair turned into the field, the dust settled, and there was

Sylvester Tinker grinning at them over the horses' cars. He was seated

on the first Tinker mowing machine.

The mower was built around a wheel 40 inches high.

Within the rim of the wheel ran a continuous s-shaped track. An arm, with

a roller attached, fitted into the track. As the wheel revolved, the

irregularity of the track gave the arm a forward and backward motion.

How It Worked.

The arm was attached to what is called a section

bar. This projects horizontally at a height regulated by the driver of the

mower. The section bar on the Tinker machine was five feet long and

cut a swath of about four feet.

A small wheel at the outer end balanced the large wheel

so that the machine could be drawn along.

The operation of the cutter, or section bar, was

similar to that of the clippers the barber uses on the back of your neck.

Instead of a set of moving points crossing over a set

of stationary ones, however, the Tinker machine had a middle bar of

moving points passing between two rows of fixed ones. The points are iron

equilateral triangles and are about four inches long on each side.

Pulled by two horses, a new machine would cut the

heaviest grass. Its success was great but largely local.

The Tinkers built about 30 machines a year

during the Civil War period and for a few years afterward.

About 150 or 200 tons of iron was the annual

consumption. The pig iron was brought to Conneaut Harbor from Buffalo in

sailing vessels.

Foundry Is Moved.

The old foundry of the original Tinker was

moved down from its ridge and established about the mill race to serve as an

assembling plant. This was manned by boys.

As many as twenty men were employed in making the parts

for the mower. They were unusually well paid - some of them as much as $3

a day, a fabulous wage for those days.

The Ford plan was not followed. Each man could

and did pour and cast any part of the machine.

The mower was doomed, however, for the famous McCormick

reaper with its whirling bars appeared in the '70s. The sales of the

Tinker product fell off.

The mower had been patented in 1856, three years after

its invention. The brothers revised it, employing some modifications of

McCormick's ideas, but were unable to obtain a patent.

They did patent parts of it, however. They were

the first to invent removable points for the section bar. They were also

the first devisers of detachable wooden guards for the stationary points.

These guards were shaped like round spearheads with a slot, and slipped on over

the points.

Built Steam Engine.

In addition to the mowing machine, the Tinkers

made a steam engine, stoves, plows, drag saws and saw mills, an apple slicer,

and a small thresher, which was operated through a system of gears on power

furnished by horses walking around it in circles.

The apple slicer was rather like a nutmeg grater,

turned inside out. It had an enormous ale among country housewives 50

years ago, when many of them made their winter money by slicing and drying

apples for export.

The machine consisted of two parallel wooden slats,

between which ran another strip of wood.

At the bottom of this strip, a common nail projected.

The apple was spitted on this. As the middle strip with the apple in

position was shoved downward it encountered strips of metal curved from one side

piece to the other with a sharpened edge turned up. Each of these four

strips was smaller than the last.

The effect was that of shoving the fruit through a

series of lessening circles. At the bottom was a small hole through which

the core tumbled out.

Only One Knows Secret.

William and Sylvester had done, in addition to

their inventions, one other remarkable thing.

They had discovered a way to make their iron nearly as

hard as steel. It was their own secret and they let no one else in on it.

No one, that is, except the late Julius Tinker,

father of the present William, and son of Sylvester.

Julius Tinker died June 8, of this year at the age

of 82, but not before he had taught the secret to his son. William

is the only one who now knows the process.

William Tinker now and then puts charcoal

and pig iron in the top of his 90-year-old cupola, turns on the air current, and

melts a little iron for plow points. He manufactures them almost

exclusively, save for an occasional set of sleigh runners turned out.

A plow point is a triangular, pointed and slightly

concave plat of metal, which fits at the head of the share and does the actual

digging.

Much Cheaper Than Steel.

An ordinary iron point will last for perhaps 70

acres of plowing in the sandy soil around Conneaut. Those of William

Tinker have gone more than 250 acres.

One set of points has been in use three yeas and is

still going strong. The iron points Tinker makes are about

one-third as expensive as steel ones.

William Tinker pours them in the same ladies

used by his father, his grandfather, and for all anyone knows, the original

Tinker. Anybody can watch him.

His secret cannot be detected by the eye. Neither

can it be written down like a chemical formula. You have to know how.

Several attempts have been made by plow company agents

to surprise the trick out of the practicing members of the Tinker Family.

The agents have watched everything done as it

ordinarily is, observing no divergence. Then they have picked up a point,

struck it, heard it ring like a chime and gone sorrowfully away, with the

laughter of the family pursuing them.

Likes to Tease Them.

"I like to tease them," William Tinker

said. "One man came here from the N__ Plow Co., one of the largest.

He was all dressed p, diamonds on his fingers. I knew he didn't belong

around here. He asked if he could come in. I told him 'sure': it

wasn't any farther from him to me than from me to him.

"He watched for a long time. Finally he said,

'I'd like to know how you do that.' I said. 'Well, I'll tell you. I

pour from this side of the ladle then from the other side. The iron that

comes out this side is just ordinary, but the other side is hard as steel.'

He said. 'Ah, what causes that? So I told him. "Well, you see. that

side of the ladle is cold." The agent went away from there.

One ladle will yield soft, ordinary cast iron.

The other will be the steel-like product for which he is famous.

"It must be in the pouring, isn't it?" the

reporter asked. William Tinker winked and said nothing.

Freddy Tinker, 13, stood near-by.

Clayton, 16, the other son, was not about. Clayton does not

follow the family tradition. He wants to be a dairy farmer.

His father regrets this, for he feels that Clayton

would be good at the trade.

Freddy is a Tinker, through and through.

The reporter asked him if he knew the secret - if he was going to continue the

making of Tinker iron. Freddy grinned.

"I guess prob'ly I will, soon as my dad gets time to

teach me." said the fifth generation of the Tinkers of Tinker Hollow,

and looked up at the black sides of the old cupola.

THE FOLLOWING TOMBSTONES MADE BY TINKER were photographed by Sharon Wick:

Made by Tinker they are the special metal that doesn't rust.

Sweany / Puffer / Catlin Tombstone found in City Cemetery, Conneaut, OH

There are more of the Tinker Tombstones in City Cemetery and most of the other

nearby cemeteries including West Springfield, PA